Home

Contact Us

Tank Assessment with Acoustic Emission

Tank Assessment with Acoustic Emission

A unique system for non-intrusive corrosion detection

MB Inspection now offers Acoustic Emission (AE) testing of aboveground storage tanks. This complements their already broad range of specialised, non-intrusive inspection services.

MB Inspection now offers Acoustic Emission (AE) testing of aboveground storage tanks. This complements their already broad range of specialised, non-intrusive inspection services.

AE tank assessment is a specialised procedure for assessing corrosion damage in tanks. Corrosion processes and scale fracture produce AE signals, detected by externally placed sensors. Recorded data are evaluated to exclude noise and provide a measure of corrosion damage to the floor.

AE tank assessment is a specialised procedure for assessing corrosion damage in tanks. Corrosion processes and scale fracture produce AE signals, detected by externally placed sensors. Recorded data are evaluated to exclude noise and provide a measure of corrosion damage to the floor.

The main benefit of this test is to survey a number of tanks to help determine inspection needs and priorities.

Test Procedures

Record and evaluate AE data from a tank under static, low noise conditions.

- Fill to greater than 50% capacity, isolate the tank and allow at least 12-hours settling time.

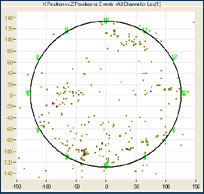

- Mount sensors on the tank (8-24 depending on tank size) and connect to an AE system.

- Calibrate, check that monitoring conditions are OK, record AE data for at least one hour.

- Pack up equipment, evaluate recorded data.

Effectiveness of Method

Using AE to assess the condition of tank bottoms has developed over the last 15-years or so. A study of the method, published in 1998, showed how AE test results compared to internal inspection findings for 148 tanks. These held a variety of products from crude oil to distillates and blended products.

The study showed that AE testing was able to tell the difference between a “good” tank and one with corrosion damage. As the chart shows, there is uncertainty in determining the amount of damage but there is a clear correlation between the AE grade and severity of damage. In particular, test reliability was highest for “good” tanks.

Benefits

- Most tanks tested within one day, minimum disruption to operations.

- Cost savings by avoiding vessel entry.

- Provides information about floor condition to aid in scheduling internal inspections.

- Permanent record of test data, ability to monitor condition over time.

For further information contact: [email protected]