Home

Contact Us

Emat Pipe Corrosion Detection

Emat Pipe Corrosion Detection

MB Inspection now offers non-contact emat scans for corrosion detection. The system is designed for rapid assessment of corrosion in piping, including normally inaccessible areas under pipe supports.

MB Inspection now offers non-contact emat scans for corrosion detection. The system is designed for rapid assessment of corrosion in piping, including normally inaccessible areas under pipe supports.

Electromagnetic Acoustic Transducers induce ultrasonic waves in metals without the need for an acoustic coupling medium. The MBI system is designed for detection and grading of corrosion in piping and under pipe supports in particular.

Although emat probes sit on the pipe surface, they are “dry coupled” and relatively unaffected by coatings and light surface rusting. The system operates by transmitting Lamb waves around the pipe circumference. The probes are held in a fixed orientation and carried along the pipe by a motor driven scanner with an encoder to track its position. Ultrasonic (thickness) data is recorded and displayed by a computer for evaluation on the spot and off-line review.

Capabilities

- Uses non-contact probes that work through most standard coatings and light surface rusting.

- Can scan up to 500 m of pipe per day depending on requirements and conditions.

- 100% coverage, detects ID and OD corrosion.

- Can detects wall losses of 10% or more depending on requirements and conditions.

- Primarily used in the inspection of carbon steel low alloy pipe work, although it is possible to apply the technique to high alloy stainless steels.

- Diameter range: 4” to 24” with development ongoing for other sizes.

Benefits

- Reduction in inspection costs through avoidance of surface preparation.

- 100% coverage including detection of corrosion under pipe supports and similar “inaccessible” places.

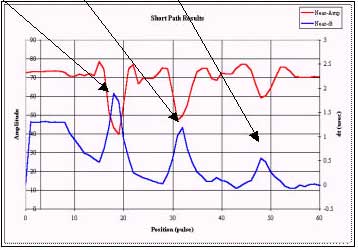

Calibration Pipe With 75%, 50% and 25% Deep Flaws

The plot displays flaw depth versus probe (axial) position. The three artificial pits are shown clearly along the length of the calibration pipe.

The plot displays flaw depth versus probe (axial) position. The three artificial pits are shown clearly along the length of the calibration pipe.