|

Secondary

Seals

Understanding

of the loss mechanisms which apply to even well designed, installed

and maintained primary seals led to the development of secondary

seals.

The main objective of secondary seals was to reduce the loss of

stored product from the primary seal area and two main types emerged:-

i) Those attached

to the primary seal.

ii) Those entirely separate from the primary seal.

There is no

doubt that the second category offers the better protection and

reference to the sketches noted will illustrate the difference between

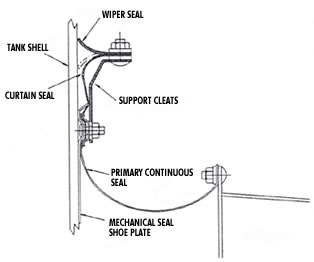

the two categories. Fig. 4 shows a small wiper seal mounted on top

of the shoe plate of an MN1 (mechanical primary seal). This is a

category i) seal and, while it prevents wind-scouring vapour losses

from the primary seal, it gives no protection if the MN1 continuous

seal material should become damaged. Fig.5 is also a category i)

seal but its secondary continuous seal material connects the wiper

seal to the floating roof pontoon and does give some protection

against a perforated primary continuous seal.

Both

seals in Figs. 4 and 5 would become ineffective if there was a gross

failure of the metal shoe plates in the primary seal. If say a pantagraph

or bazooka failure occurs then the shoe plate can move away from

the tank shell, taking the secondary seal wiper with it and permitting

vapour leakage from the resulting gap.

Fig. 4 |

Fig. 5 |

Fig. 6 shows

a category ii) seal where the secondary seal is completely independent

of the primary seal and continues to function even where gross failure

of the primary seal has occurred. The example shown has a metal

compression plate (similar to early windshields but with each leaf

joined and sealed to its neighbours). This gives additional protection

to the primary continuous seal from falling debris etc. and therefore

is clearly preferable to category i) seals.

Variations

of the category ii) seals are:-

Fig. 7 similar

to Fig. 6 but with a suspended vapour barrier of polyurethane connecting

the wiper seal to the floating roof instead of using sealed joints

in the metal compression plates. This is likely to be more expensive

than the sealed plate type and the polyurethane membrane may be

adversely affected by water vapour.

It should be

noted that fitting a secondary seal to a tank could involve slight

loss of useable liquid space since it projects above the primary

seal. This is only true of course if the tank does not have a windskirt

at the top of the shell and if the secondary seal must be kept below

the highest level of the tank shell. The Motherwell Nayler Petroseals

secondary seal (Fig. 8), can be taken beyond the top of the tank

shell without damage to the seal system, provided prior notice is

given. Of course, the full benefits of the secondary seal will not

be available at those times when the seal is above the shell top.

|