|

Metallic

Seals

MN-1 Metallic

Seal

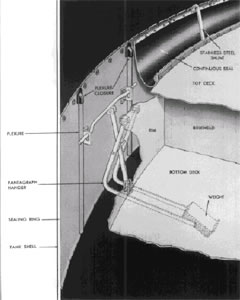

The MN-1

Metallic Seal with Pantagraph Hangers is the most widely used of

all floating roof seals.

It consists

of a ring of galvanised steel shoe plates, the bottom of which remains

below the liquid surface. A continuous vapour-tight and weatherproof

synthetic rubber-coated fabric is used to close the space between

the sealing ring and the rim of the floating roof. The lower edge

of the fabric is bolted to the edge of the floating roof. The upper

edge of the fabric is attached to the top of the shoe plates.

The shoe plates

are supported and held firmly, but gently, against the tank shell

by pantagraph hangers which apply a uniform outward radial pressure.

The light pressure minimises abrasion of the shoe plates and of

tank-shell coatings.

The pantagraph

hangers automatically keep the roof centred in the tank. If the

roof should tend to move off centre, the pressure of the hangers

will increase on the side where the rim space is the narrowest.

This action automatically corrects the roof location.

The pantagraph

hangers will accommodate a rim space variation of plus-or-minus

five inches (127mm) from nominal dimensions. Each is ruggedly built

to have sufficient reserve strength to operate even if its section

is greatly reduced by corrosion. Pantagraph hangers are recommended

for use in all types of service, including the storage of corrosive

products.

An MN-1 Metallic

Seal with Pantagraph Hangers will retain its vertical position even

when the shoe plates extend above the top of the tank shell. Thus,

the sealing ring will not be damaged even if the tank is filled

to overflowing. It will remain centred, and return into the tank

safely and easily when the product is withdrawn. The knee of the

pantagraph hanger accounts for this desirable feature. When hangers

without this feature are used, a tank shell extension is required.

In order to

accommodate variations in tank diameter and circumference, there

must be provision for expansion and contraction of the sealing ring.

The MN-1 shoe plates provide for expansion and contraction with

vertical flexures spaced approximately 22 inches (559mm) apart.

These flexures serve both as stiffeners to distribute hanger pressure

over the height of the shoe plates, and as hinges which allow them

to conform to the curvature of the tank shell. Since the flexures

are an integral part of the shoe plates, this construction results

in a one-piece metallic sealing ring around the entire periphery

of the tank without the need for inter-shoe seals.

The continuous

fabric used to close the rim space is resistant to up to 100% aromatics.

Antistatic and low flame grades are also produced.

Stainless steel shunts above the continuous seal provide sure electrical

bond between the floating roof and the shoe plates which are in

contact with the tank shell. These shunts reduce the chance of lightning

ignition.

MN-2 Metallic

Seal

The

MN-2 Metallic Seal is specially recommended for riveted or lap-welded

tanks. They can sometimes overcome sealing difficulties where tank

shells have become badly deformed.

The MN-2 Metallic

Seal acts in a similar manner to the MN-1 Seal except that additional

provision for expansion and contraction is made with inter-shoe

seals of rubberised fabric. These intershoe seals are spaced from

50 to 60 feet (15.2 to 18.3m) apart and provide extra lateral flexibility

to the sealing ring.

Accessories

for Metallic Seals

Wax Scrapers

Wax scrapers

may be fitted to metallic seals on butt-welded tanks handling waxy

crude. They minimise problems resulting from a layer of waxy material

on the tank shell above the floating roof, melting from the sun’s

heat, and flowing down the shell onto the roof.

The wax scrapers

are made from 1.6mm galvanised sheets and are attached to the shoe

plates. The scraper portion is below the main sealing ring. The

reservoir portion above the sealing ring collects the wax which

melts down from the shell and prevents it from flowing onto the

roof.

Sole Plates

Sole plates

are added when metallic seals are used in riveted or lap-welded

tanks. They assist the shoe plates in riding over rivets and plate

edges. Sole plates are made from 1.6mm galvanised sheets and are

flared at the top and bottom. Since they are bolted only at the

top where they are connected to the shoe plates, they may be removed

easily from above.

Wear Plates

Wear Plates

are used to extend the life of the shoe plates by adding an additional

wearing layer which may be replaced conveniently when worn out.

Wear plates are similar to sole plates except that the length of

flare is reduced, and the height of the wear plates is approximately

the same as the shoe plates.

Shoe Plate

Secondary Seals

Shoe plate secondary

seals can be fitted to increase the efficiency of a metallic seal.

A rubber loop is fitted at the top of the shoe plates to prevent

the wind from sweeping vapour out from between the shoe plates and

the tank shell.

They should

preferentially be used on riveted or lap welded tanks storing gasoline

or other volatile stocks, because rivets and laps hold the shoe

plates some distance from the shell.

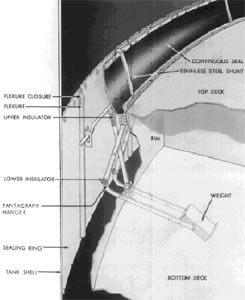

Insulated

Pantagraphs

In tanks storing

low vapour pressure stocks, floating roofs with metallic seals can

be equipped with insulated pantagraph hangers for added protection,

especially in areas having frequent electrical storms.

Insulated pantagraph

hangers and shunts protect the floating roof from damage through

lightning.

|